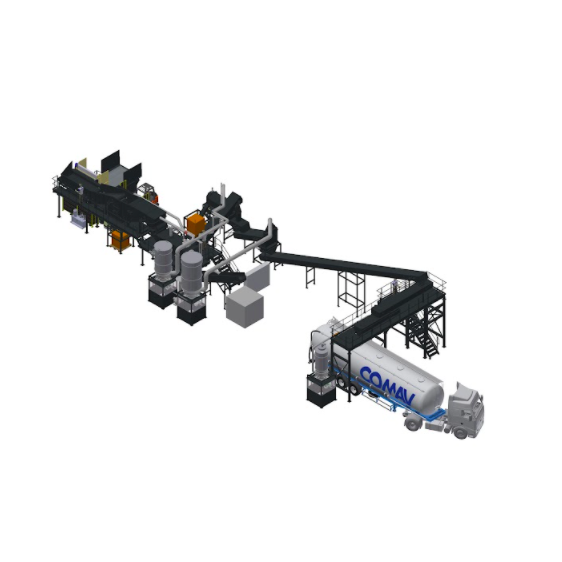

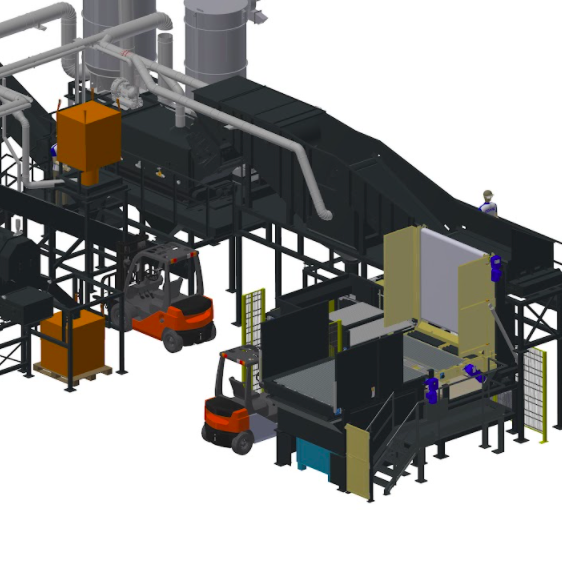

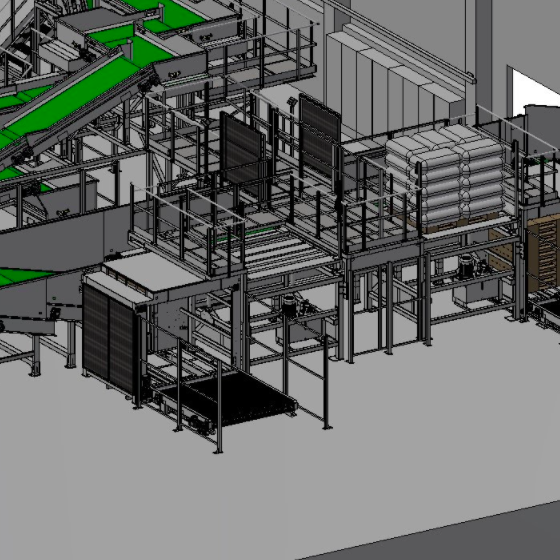

COMAV is not just a reliable partner for the supply of different parts and automatic machines. We combine our in-depth knowledge of production processes with creation of special machines and solutions for handling raw materials in solid form, or in the form in which the products are received by our customers.

From here, over the years, we have gained the experience and knowledge to solve numerous problems with custom-built projects, scaled in response to the client’s specific requirements, combining integration of new, Industry 4.0 automated technologies with innovative mechanical elements.

Our Special Projects division includes Big Bag emptiers, Octabin tilters, bag emptying machines, automatic drum cutter machines and knife gate and rotary diverter valves, for key-in-hand systems that cover everything from conveying bags and tipping containers to palletising systems.

Please send us your enquiries and we will analyse the feasibility of your project.